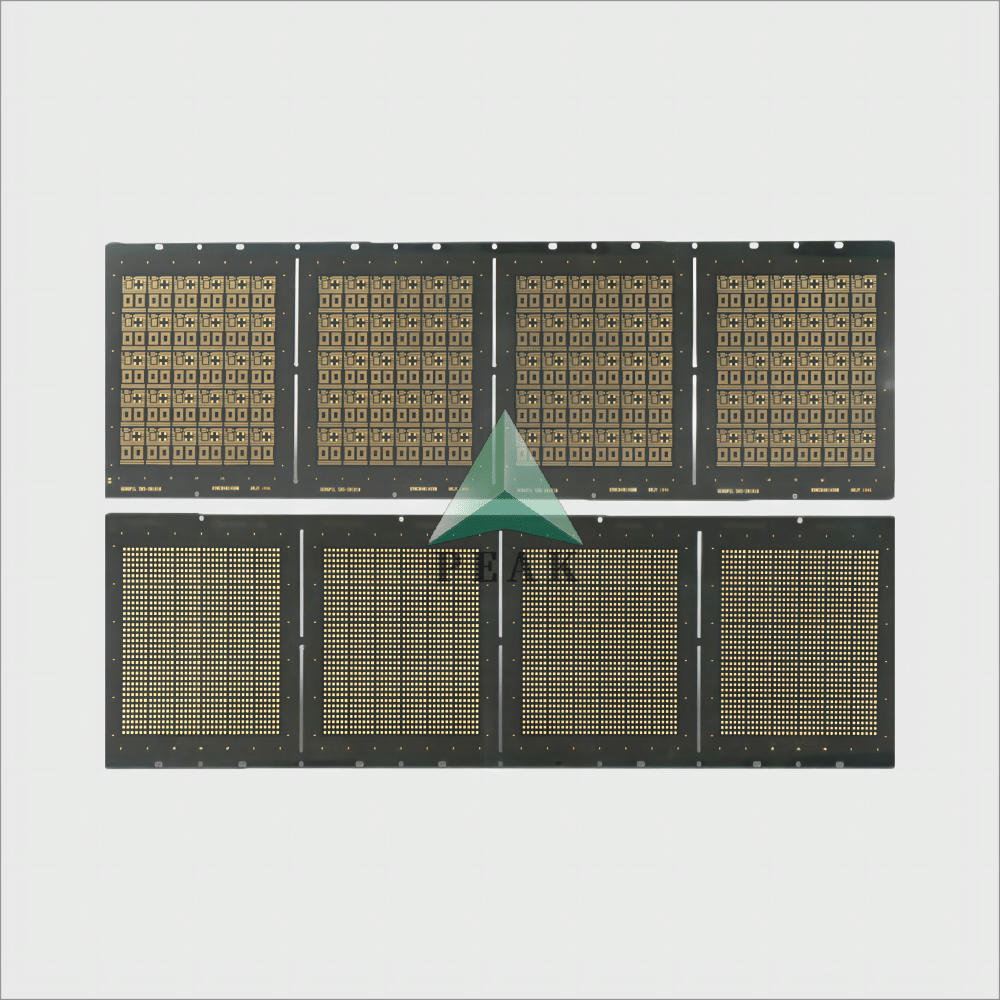

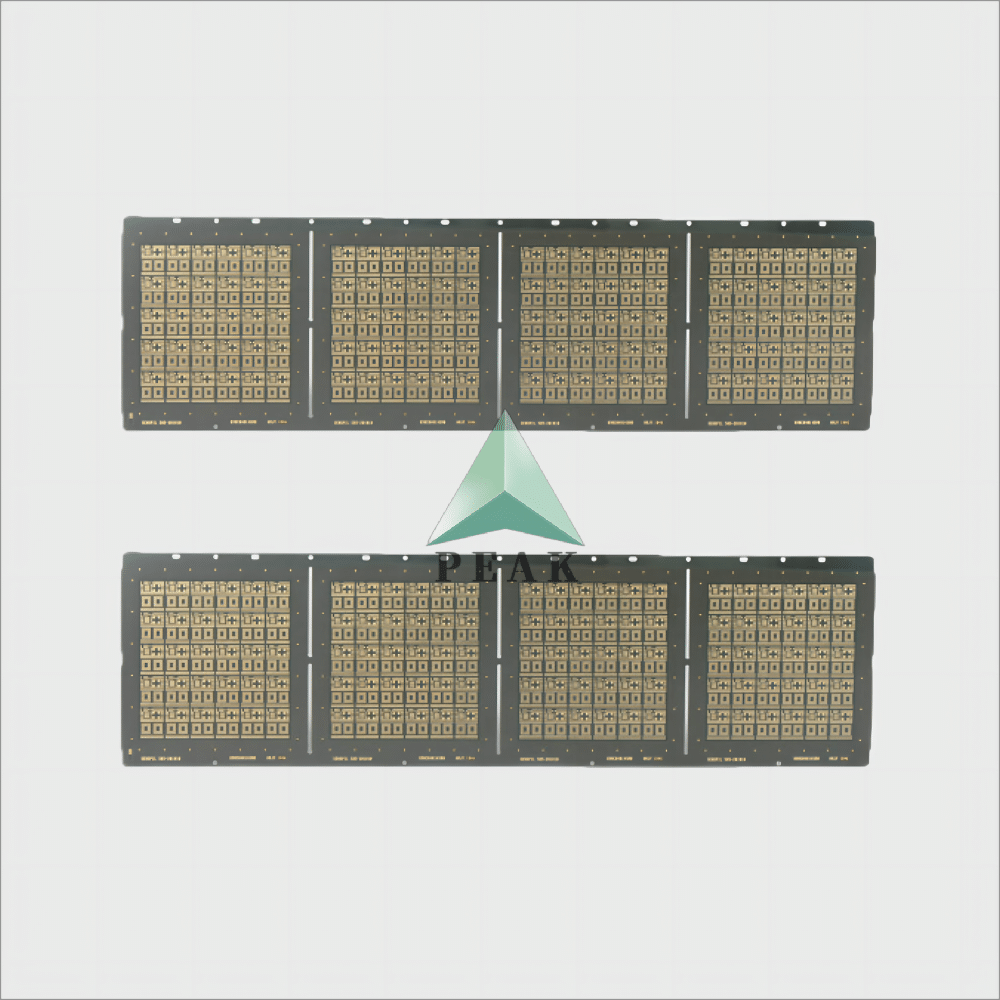

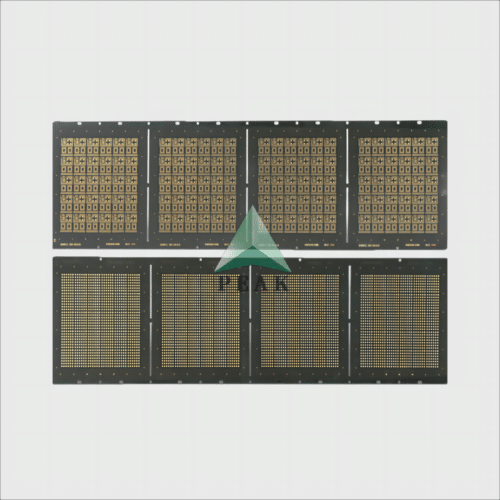

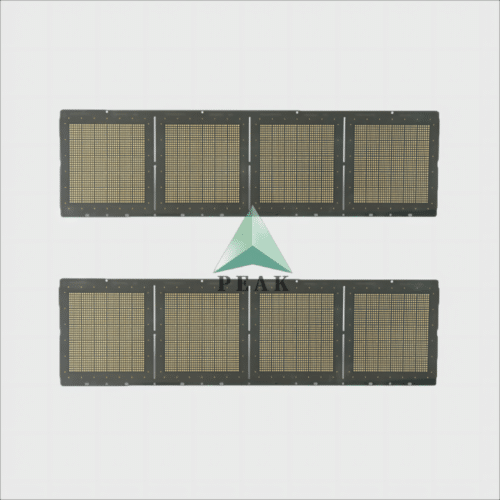

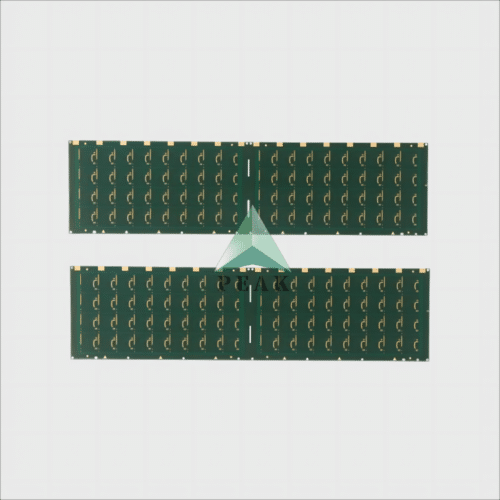

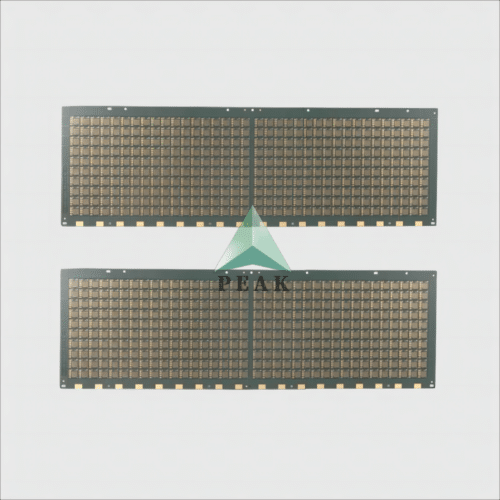

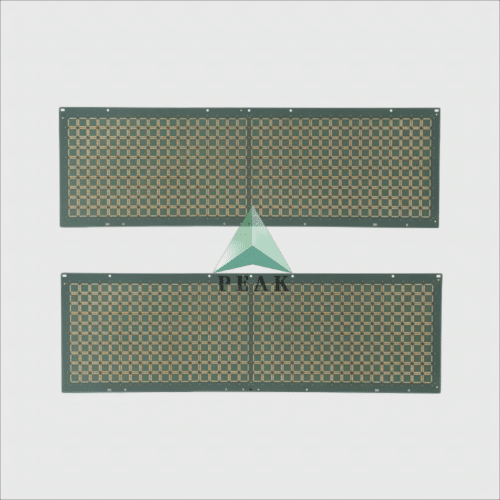

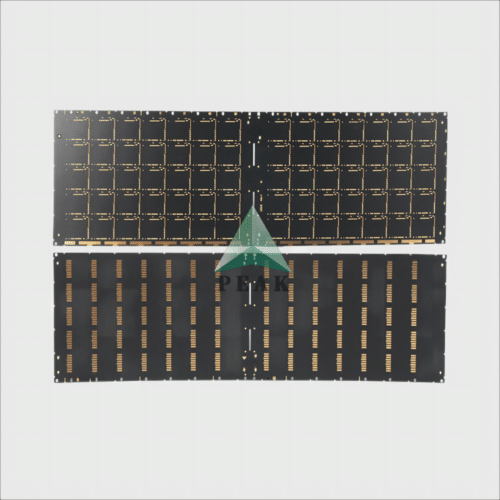

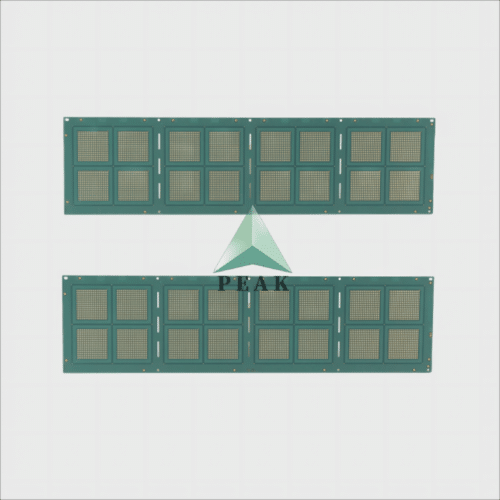

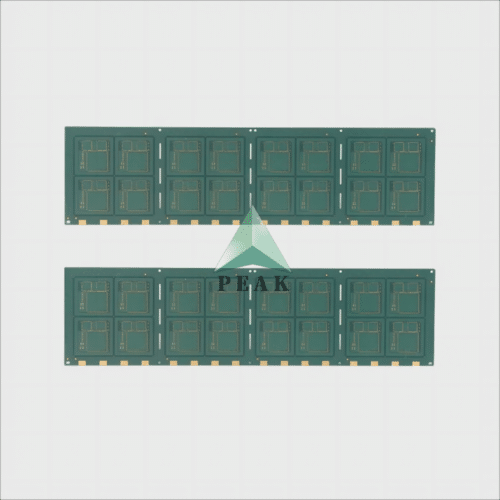

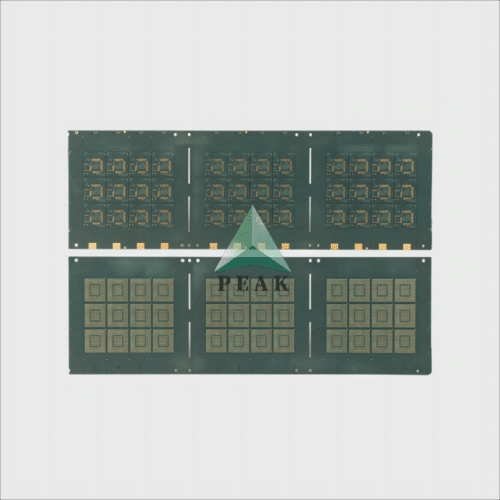

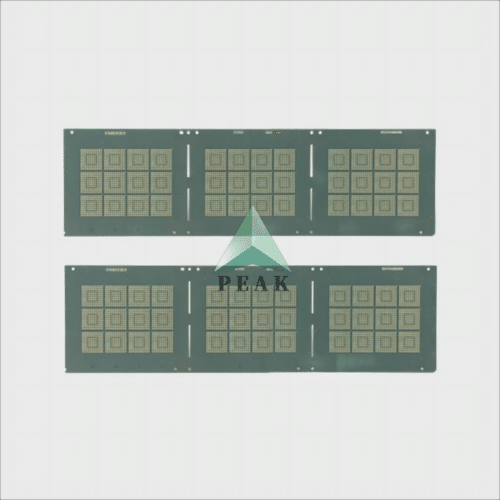

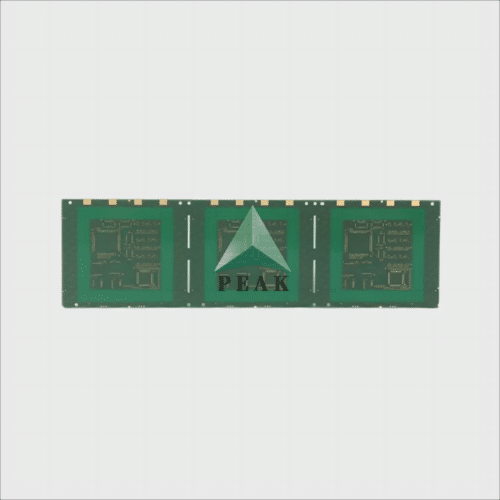

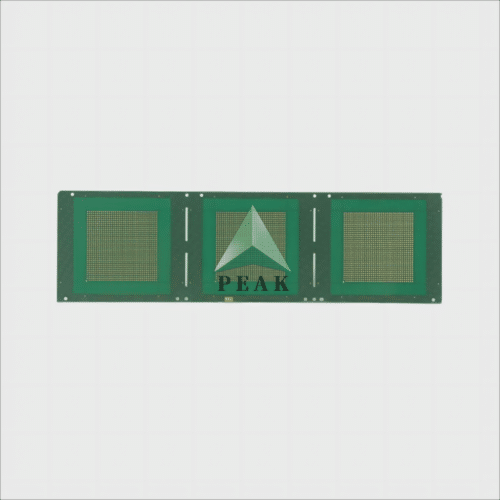

Brand Name : PEAK PCB

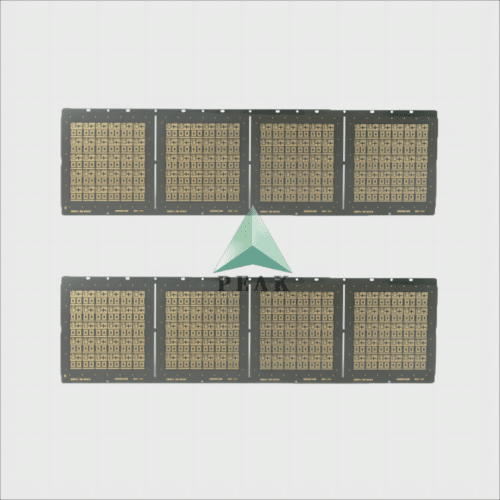

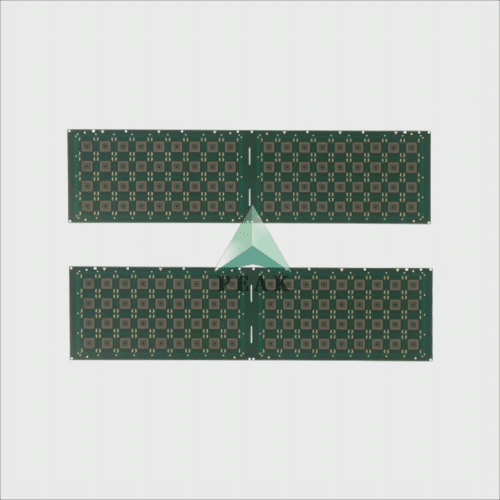

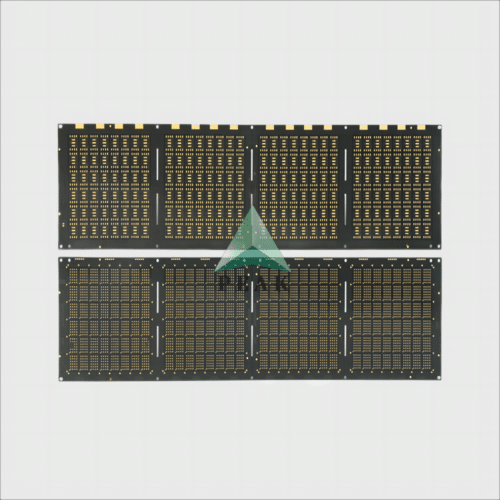

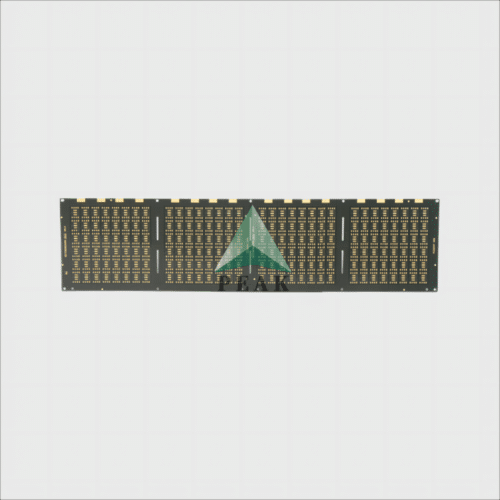

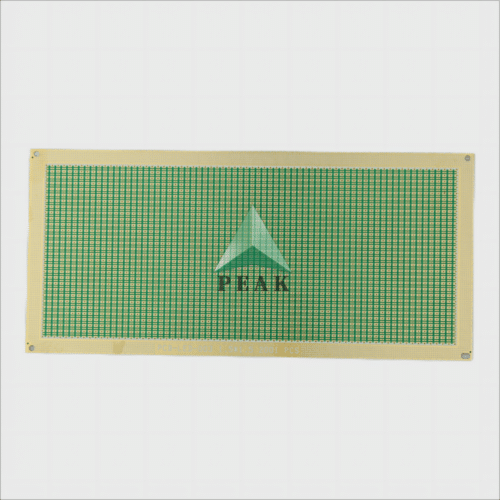

PCB Type : Substrate PCB

Number of Layers : 2 Layers (Max 64 Layers)

Finished Thickness : 0.2 mm (Max 8mm)

Base Material : MITSUBISHI GAS HL832NXA

Finished Inner Copper Thickness : 0oz (Max 14oz)

Finished Outer Copper Thickness : Hoz (Max 14oz)

Min. Hole : 50um

Min. Line Width : 25um

Min. Line Spacing : 75um

Surface Finishing : ENEPIG

Solder Mask : Black

Silk Screen : No

Thickness Tolerance : ±5%

Impedance Control Accuracy : ±10% (min±5%)

Outline Profile : Rout/ V-cut/ Bridge/ Stamp Hole

Testing Service : 100% AOI ICT FCT Testing

Special Processes : No

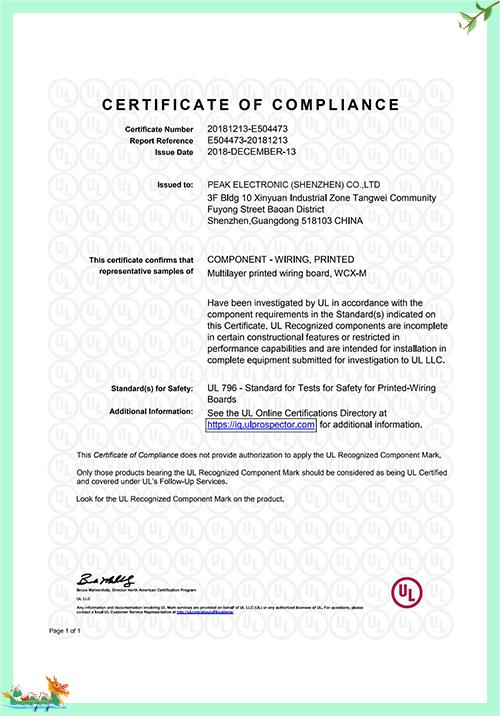

PCB Standard : IPC-A-610 E Class III

Application : Electronic Device

Supply Ability : Sample and Mass Production

Place of Origin : Guangdong, China

Packaging Inner : Vacuum Packing/ Anti-Static Package

Packaging Outer : Export Carton/ Customizable

Port : Shenzhen, Hongkong

Acceptable File Format : Gerber file, Powerpcb, CAD, AUTOCAD, ORCAD, P-CAD, CAM-350, CAM2000

What is Multilayer PCB?

Multilayer PCB or Printed Circuit Board is a type of board which is used in electronic devices. As the name suggests, it consists of multiple layers of copper conducting paths that are separated by an insulating material called substrate. It is used in high-end electronic devices because of its advantages over the traditional single-layered PCBs.

Multilayer PCBs are made up of multiple layers of conducting paths and insulating materials. These layers are then laminated together to create a single board. The number of layers in a Multilayer PCB can vary depending on the application of the device. Some Multilayer PCBs can have up to 30-40 layers, whereas others may have fewer layers.

The biggest advantage of Multilayer PCBs is their ability to handle complex circuits and designs. Single-layered PCBs have a limited number of components that can be placed on them. However, Multilayer PCBs can accommodate a higher number of components because of their multiple layers. This makes it possible to design more advanced electronic devices.

Multilayer PCBs are also more reliable and durable than single-layered PCBs. The multiple layers provide additional support and stability to the board, making it less prone to damage. The insulating substrate material used in Multilayer PCBs is also more heat-resistant and can withstand higher temperatures without degrading.

Another advantage of Multilayer PCBs is their ability to reduce electromagnetic interference (EMI). The multiple layers of conducting paths in Multilayer PCBs allow for better shielding of the components, reducing EMI. This is particularly important in sensitive electronic devices where EMI can cause interference and disrupt the functioning of the device.

In conclusion, Multilayer PCBs are a superior alternative to traditional single-layered PCBs. They offer the ability to handle complex circuits, are more reliable and durable, and can reduce electromagnetic interference. Multilayer PCBs are widely used in high-end electronic devices such as smartphones, laptops, and other advanced electronic devices.

Have other questions about Multilayer PCBs?

1. What is a multilayer PCB?

2. What are the advantages of using a multilayer PCB over a single-layer PCB?

3. How many layers can a multilayer PCB have?

4. What are the different types of multilayer PCBs?

5. What materials are used to make multilayer PCBs?

6. What are the typical applications of multilayer PCBs?

7. What is the process for designing and manufacturing a multilayer PCB?

8. How are the layers of a multilayer PCB interconnected?

9. Can multilayer PCBs be repaired if they become damaged?

10. How do I choose the right multilayer PCB for my project?