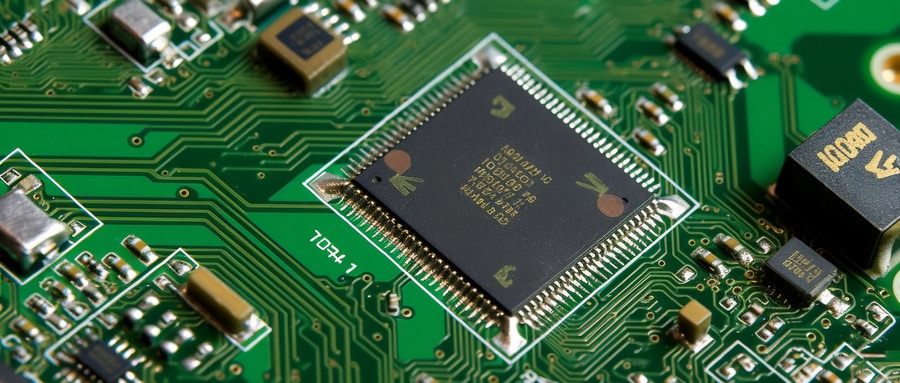

The Anatomy of Multilayer PCBs: How Many Layers PCB Can Have ?

Printed Circuit Boards play a vital role in the dynamic worlds of electronic design and manufacture. The unique, intricate design of PCBs has revolutionized the world of technology, giving power to small, sleek devices. PCBs are often discussed in terms of their number of layers.How Many Layers PCB Can Have ?

A PCB is available in a variety of versions, from single-layer boards to multilayer boards that can reach up to 100 layers. Most PCBs are between 4 and 12 layers. Each layer adds new dimensions to the design of devices, but also increases production costs and time.

How Many Layers PCB Can Have ? The single-sided PCB is the most basic type of PCB. All the circuits and electrical components are arranged on the same side. They are used in many electronic products due to their low cost of production.

How Many Layers PCB Can Have ? Double-layer PCBs, or double-sided, are the next step. They consist of two-sided boards, with components and circuits on both sides. The two sides are connected through plated-through-holes (PTH). They offer more design flexibility and are used for more complex devices such as power supplies and relays.

How Many Layers PCB Can Have ? The Multilayer PCBs can have anywhere between 4 and 100 layers. These PCBs are a huge advantage for high-speed circuitry and advanced electronic equipment like GPS, data storage and satellite systems. With the development of increasingly compact and sophisticated electronics, the use of multilayer printed circuit boards has increased dramatically.

How Many Layers PCB Can Have ? The 4-layer PCB is a multilayer PCB that consists of two layers of conductive materials surrounded by insulating material. Four-layer PCBs can be found in many devices with moderate complexity, such as industrial controls and hard disk drives.

How Many Layers PCB Can Have ? High-layer PCBs are those with more than four layers. These boards are used in areas that require high-density and complex designs. This includes sophisticated communication equipment as well as complex industrial controls and intricate medical machinery.

How Many Layers PCB Can Have ? PCBs up to 100 layers thick are used by organizations that have specific requirements, such as the aerospace or defense industries. Despite their complexity and high costs, it’s important to note that PCBs with a very high layer count aren’t widely used.

Remember that the number and size of layers on your PCB will directly impact its functionality and cost. Understanding the optimal number of layers for a device or system can be crucial to ensuring efficient performance, size and cost considerations.

The number of layers that a PCB has is determined by its specific functions, objectives, budget, and complexity. In deciding the number of PCB layers, the balance between cost and functionality will always be the determining factor.

Every PCB, whether it is single-sided or double-sided and multi-layered, is a testament to the technological advances of today, as well as the unending drive for innovation. Future developments, miniaturizations, and the need for more complex devices could push the limits, adding more layers to PCBs, while continuously reducing their size, and improving their performance. Understanding the many facets of PCBs is the first step to understanding the benefits and challenges of the evolving electronics.

Multilayer PCBs are a key element of various electronic gadgets and are likely to face more advancements as technology continues to evolve. Here are a few predictions for the future of multilayer PCB:

1. Miniaturization: With the demand for smaller and more powerful electronic devices, the size of PCBs is set to reduce further. This could lead to more layers being added to the boards to meet the required needs.

2. Improved materials: Advancement in materials such as using high performance resins could give rise to superior thermal management, lower losses and better mechanical stability.

3. Enhanced design software: As the complexity of multilayer PCBs increases, the need for more sophisticated design software is inevitable. Future software programs might offer better simulation and debugging features, thereby reducing the time and cost involved in designing and testing new PCBs.

4. More Environmentally Friendly: Given the current focus on sustainability, the future of multilayer PCBs will more than likely involve components that have a lower environmental impact, both in terms of their production and their disposal.

5. Advanced technologies: With developments in areas such as IoT, 5G, and AI, multilayer PCBs will have to support advanced technologies and applications. This could include embedded components, flexible PCBs, and high-speed data transfer capabilities.

6. Improvement in Manufacturing Processes: The manufacturing processes will become more sophisticated with techniques such as additive manufacturing and digital fabrication, which will not only increase efficiency but also allow for more complex PCB designs.

This is just a glimpse of the potential progress expected in PCB technology, which is sure to experience a lot more transformations as the electronic and technical needs of society continue to evolve.