Unraveling the Gilded Edge: Gold Fingers PCB Design and their Implications on Performance

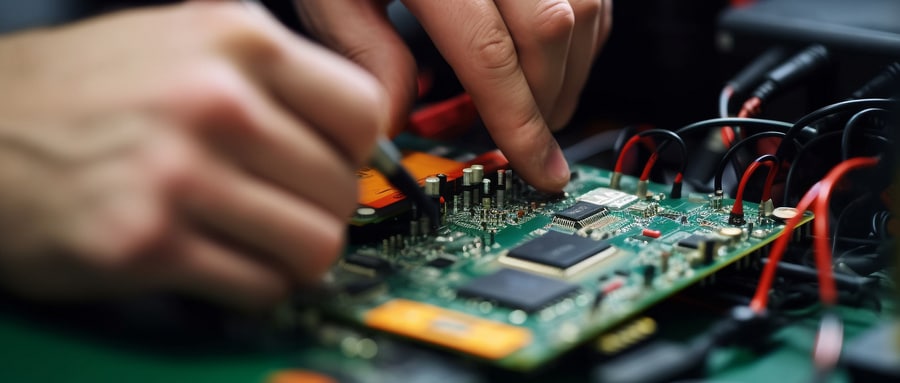

In the world of Printed Circuit Boards (PCBs), ‘Gold Fingers’ are not just appealing due to their glistening presentation. These seemingly delicate structures hold a world of significance for the PCB, right from its functionality to its ability to withstand multiple insertion and removal cycles. This article serves as a guide to understanding Gold Fingers, their application in PCB design, and the impact they create on the performance of an electronic device.

Deciphering Gold Fingers PCBs

When we talk about Gold Fingers, we’re referring to the exposed golden edge connectors on a PCB. Implementing Gold Fingers PCB design essentially means that a specific section of the PCB is gold-plated to sustain repeated insertion and removal cycles when attached to a mating edge connector in another gadget.

The Building Blocks of Gold Fingers

The manufacture of Gold Fingers commences with a foundational copper layer, over which a thin layer of nickel is applied. This nickel layer serves two core purposes – it acts as an adhesion layer for the gold while also serving as a barrier to prevent the copper from migrating to the gold layer, which could lead to the degradation of Gold Finger’s performance.

The final layer is the gold plating, with Hard Gold or Electrolytic Gold being the most commonly used due to its durability and resistance to wear and tear.

Delving into the Benefits of Gold Fingers

Gold Fingers confer numerous advantages to a PCB, making them an important element in PCB design.

- High Conductivity: Gold possesses one of the highest electrical conductivity rates among metals, which enhances the performance of the edge connector.

- Reliable Contacts: Gold Fingers ensure reliable contact, resulting in consistent connectivity, given gold’s anti-oxidation properties.

- Durability: Gold fingers enhance durability and withstand repeated cycles of insertion and removal due to the hardness of Electrolytic Gold.

Guidelines for Incorporating Gold Fingers

While including Gold Fingers elevates PCB functionality, their proper implementation requires understanding and following specific guidelines.

- Chamfering: The Gold Fingers should ideally be chamfered at a 45-degree angle to make the insertion process smooth, reducing potential wear and tear on the connector.

- Clearance: Avoid placing any components or via holes close to Gold Fingers to prevent potential damage or contamination during the gold plating process.

- Orientation: Always orient the Gold Fingers toward the board’s edge, which allows for efficient connection and disconnection.

The role of Gold Fingers in PCB design extends beyond simply enhancing its aesthetics—it is a game-changer, marking the difference between a high-functioning, durable PCB and a standard one. With high conductivity, reliability, and robustness, Gold Fingers significantly enhance the PCB’s operational excellence, reinforcing their indispensability in PCB design.

This exploration of Gold Fingers PCB design underscores their role in ensuring seamless connectivity, longevity, and continued performance in the world of electronics. As we delve deeper into the electronics universe, these golden connectors pave the way for a broader understanding of how purposeful design alterations can yield exponential returns in performance and reliability. And with this understanding, we find ourselves in awe of how a golden touch can transform the face of PCB design and functionality. Indeed, the marvel of Gold Fingers extends beyond what meets the eye.

FAQ:

- Q: What are Gold Fingers PCB?

A: Gold fingers are the gold-plated connectors that are along the edge of a Printed Circuit Board (PCB). They are used to connect one card or board to another in order to establish an electronic link. - Q: Why are they called Gold Fingers?

A: They are called “Gold Fingers” due to their appearance – they look like a row of golden fingers protruding from the edge of the PCB. - Q: Why is gold used for the fingers on a PCB?

A: Gold is used because it’s an excellent conductor of electricity and doesn’t corrode or oxidize, making it highly reliable for long-term connections. - Q: Are all Gold Fingers made out of pure gold?

A: No, most gold fingers are composed of a base material such as copper, plated with a layer of nickel, and then a thin layer of gold. - Q: How are Gold Fingers created on a PCB?

A: Gold fingers are typically created through a process called electroplating. This involves plating a layer of nickel followed by a thin layer of gold onto the designated finger region. - Q: Can Gold Fingers be on both sides of a PCB?

A: Yes, Gold Fingers can be located on one side, both sides or multiple locations on a PCB depending on the design and application requirements. - Q: What precautions should be taken when handling PCBs with Gold Fingers?

A: Care should be taken not to scratch, dent or soil the Gold Fingers, as it may impair their functionality. Always handle PCBs by the edges, and avoid touching the Gold Fingers directly. - Q: Does having Gold Fingers make a PCB more expensive?

A: Yes, the process of gold plating does add to the cost of the PCB. However, the improved connectivity and reliability often justify the additional cost. - Q: Are Gold Fingers used only in PCBs?

A: No, Gold Fingers are also used in other types of electronic connectors, such as those in computer memory cards, and audio and video equipment. - Q: Are there alternatives to Gold for plated fingers?

A: Yes, other materials such as silver or palladium-nickel can be used, but typically gold is preferred due to its superior conductivity and resistance to corrosion.