Control PCB: a vital part of electronics-16 years control PCB manufacturer

-Control PCB: The Brain of Modern Electronics

In today’s world, electronics are an integral part of our lives. From smartphones to computers, from automobiles to medical devices, electronics surround us everywhere we go. These devices are made up of various components, one of which is the control PCB (Printed Circuit Board).

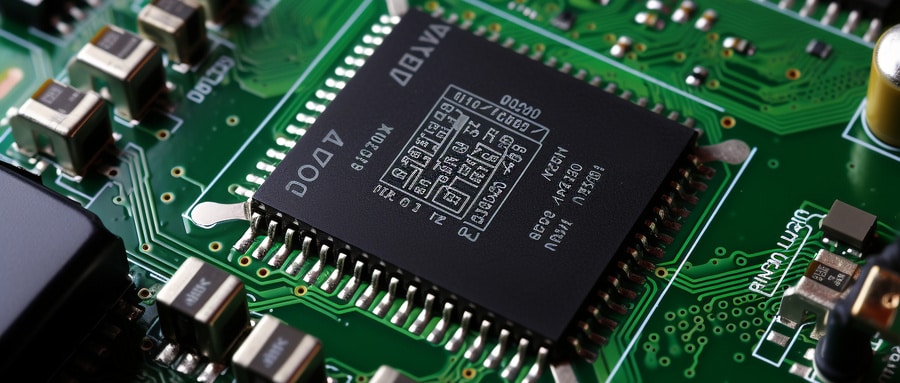

A control PCB is a small board made up of conductive tracks, pads, and other components that are used to connect and control the different parts of an electronic device. The PCB acts as the brain of the device, controlling its functions and operations.

The control PCB is essential for the proper functioning of an electronic device. It is responsible for managing the flow of data and signals between different components and ensuring that they work in harmony. The PCB also provides power to the different components of the device, making it possible for them to function correctly.

The design of a control PCB is critical to the performance of an electronic device. The layout of the board must be optimized for the specific application it is intended for, taking into consideration the size of the device, the power requirements, and other factors. The design must also be robust enough to withstand the stresses and strains of daily use.

Control PCBs are used in a wide range of electronic devices, from simple household appliances to complex industrial machinery. They are also used in medical devices, such as MRI machines and heart monitors, where precision and accuracy are critical.

The production of control PCBs requires specialized equipment, such as computer-aided design (CAD) software and automated assembly machines. The manufacturing process involves etching the circuit pattern onto a copper-clad board, mounting the components onto the board, and then testing the board for functionality.

In recent years, there has been a growing interest in the development of flexible and wearable electronics. These devices require control PCBs that are lightweight and flexible, allowing them to bend and conform to the shape of the body. Researchers are exploring new materials and manufacturing techniques to create these flexible control PCBs.

In conclusion, the control PCB is a vital component of modern electronics. It acts as the brain of the device, controlling its functions and operations. The design of the PCB is critical to the performance of the device, and its production requires specialized equipment and expertise. As technology continues to evolve, the development of flexible and wearable electronics will require new innovations in control PCB design and manufacturing.

-Control PCB design points

The design of a Printed Circuit Board (PCB) plays a crucial role in the overall functioning and performance of electronic devices. As such, it is important to pay attention to the critical control points in the PCB design process to ensure optimal functionality and reliability.

One of the primary control points in PCB design is the placement of components. The placement of components on the board should be optimized to ensure that they are easily accessible and that they do not interfere with other components. Additionally, the placement of components should be such that they are easy to replace if necessary.

Another important control point in PCB design is the routing of traces. It is essential to ensure that traces are routed in such a manner that they are not too close to each other. This helps prevent signal interference and crosstalk. The routing of traces should also be optimized to minimize the length of the traces, as this helps reduce the overall resistance of the circuit and, consequently, improves performance.

The power supply design is another crucial control point in PCB design. The power supply should be designed to provide stable and reliable power to the components on the board. This requires careful consideration of the power requirements of each component and the overall power consumption of the device. It is also important to ensure that the power supply is properly grounded to prevent noise and interference.

In addition to the above, the thermal design of the PCB is also an important control point. Electronic components generate heat, and if this heat is not dissipated properly, it can lead to reduced performance and even failure. The thermal design of the PCB should, therefore, be optimized to ensure that heat is dissipated efficiently and that the temperature of the components remains within safe limits.

Finally, it is important to pay attention to the overall layout of the PCB. The layout should be optimized to ensure that it is easy to manufacture and assemble. It should also be designed to meet any specific requirements of the device, such as size or weight limitations.

In conclusion, the design of a PCB is a complex process that requires careful attention to several critical control points. By optimizing the placement of components, routing of traces, power supply design, thermal design, and overall layout, designers can ensure that their PCBs are reliable, functional, and efficient.