Automated PCB Assembly: The Future of Electronics Manufacturing

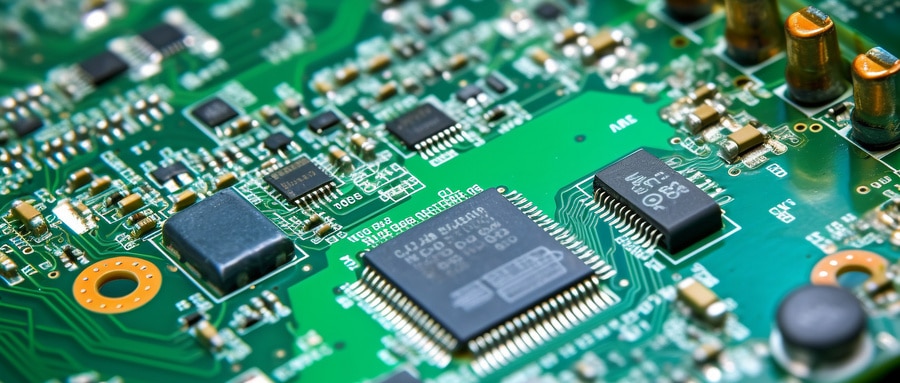

Printed Circuit Board (PCB) Assembly is a critical process in the electronics manufacturing industry. A PCB is an electronic board that connects and supports the electronic components of a device. The process of PCB assembly involves placing electronic components on the board and soldering them in place. Manual PCB assembly is a time-consuming and labor-intensive process that requires a high level of expertise. However, automated PCB assembly is revolutionizing the electronics manufacturing industry, making the process faster, more efficient, and cost-effective.

Automated PCB assembly involves using machines and robots to place electronic components on the board and solder them in place. The process is faster, more accurate, and less prone to errors than manual assembly. Automated assembly machines can handle large volumes of PCBs and can work around the clock without fatigue or errors.

One of the key advantages of automated PCB assembly is its ability to improve quality control. The machines are equipped with advanced sensors and cameras that can detect defects and errors in the assembly process. This ensures that the finished product is of high quality and meets the required standards.

Another advantage of automated PCB assembly is its ability to reduce costs. The machines can work faster and more efficiently than human workers, which reduces the cost of labor. Additionally, the machines can use materials more efficiently, reducing waste and material costs.

Automated PCB assembly also offers flexibility in terms of customization. The machines can be programmed to handle different types of PCBs and electronic components, making it easy to customize the assembly process for different products. This means that manufacturers can produce a wide range of products with different specifications without having to invest in new equipment.

The use of automated PCB assembly is expected to increase in the coming years, driven by the need for faster, more efficient, and cost-effective manufacturing processes. As the electronics industry continues to grow, the demand for PCBs and electronic components is expected to increase, and manufacturers will need to find ways to meet this demand while maintaining quality and reducing costs.

In conclusion, automated PCB assembly is the future of electronics manufacturing. It offers faster, more efficient, and cost-effective manufacturing processes while maintaining high levels of quality control. As the electronics industry continues to evolve, manufacturers who adopt automated PCB assembly will have a competitive advantage over those who rely on manual assembly processes.

How to choose a good automated PCB assembly manufacturer?

Choosing a good PCB assembly manufacturer is crucial to ensure the quality and reliability of your electronic products. When looking for a manufacturer, consider their experience and expertise in the industry, their certifications and compliance with industry standards, and their ability to provide customized solutions to meet your specific requirements. You should also check their track record and customer reviews to ensure their credibility and reliability. Additionally, consider their production capacity, lead times, and pricing to ensure that they can meet your production needs and budget. Finally, communication and collaboration are essential, so look for a manufacturer who is responsive, transparent, and willing to work closely with you throughout the manufacturing process.

Another important factor to consider when choosing a PCB assembly manufacturer is their technical capabilities. Look for a manufacturer who uses advanced technology and equipment to ensure the highest quality and efficiency in the manufacturing process. They should also be able to handle complex designs and components and offer testing and quality control measures to ensure the final product meets your specifications.

In addition, a good PCB assembly manufacturer should provide excellent customer service and support. They should be able to answer your questions and concerns promptly and offer technical assistance when needed. They should also be able to provide ongoing support after the product is delivered, such as repairs and replacements if necessary.

Finally, consider the location of the manufacturer. Choosing a manufacturer that is located near your business or shipping destination can save time and money on shipping and logistics. However, don’t compromise on quality and reliability for the sake of convenience.

In summary, choosing a good PCB assembly manufacturer requires careful consideration of their experience, certifications, technical capabilities, customer service, and location. By taking the time to research and evaluate potential manufacturers, you can ensure that your electronic products are of the highest quality and reliability.