Green Culture

As a company with 16 years of experience in circuit board production, we understand the importance of environmental protection and sustainable development for our company. We always adhere to the people-oriented approach and focus on the health and safety of our staff, while actively responding to the national call to continuously improve our corporate social responsibility system and make contributions to society.

In the production process, we take a series of environmental protection measures to reduce the emission of waste gas, waste water and waste residue, and ensure that the treatment of pollutants meets the national emission standards. We increase investment in environmental protection facilities to ensure that pollutants are effectively treated. In addition, we continue to explore more environmentally friendly production processes for circuit boards by increasing our investment in environmental research and development to achieve green production.

In terms of corporate management, we put people first and focus on the health and safety of our employees. We take a series of measures to ensure a safe and comfortable working environment for our employees and to avoid occupational diseases and accidents. At the same time, we also actively respond to the call of the state, continuously improve our corporate social responsibility system, actively participate in social welfare and make contributions to society.

Taking the road of sustainable development is the core of our corporate green culture. We strive to achieve sustainable development of our enterprise from multiple perspectives, such as enterprise management, technological innovation and product design. We improve the management efficiency and level of the enterprise by optimizing the enterprise management system, and reduce the resource consumption and environmental pollution of the enterprise. At the same time, we also actively explore green ways of technological innovation and product design to provide customers with more environmentally friendly products and services.

Corporate green culture not only contributes to environmental protection and sustainable development, but also brings economic benefits and social reputation to the enterprise. Therefore, we keep exploring and innovating in practice to integrate green culture into the development strategy and daily operation of the enterprise. Meanwhile, the government, enterprises and the whole society should work together to promote the popularization and development of corporate green culture and contribute to the goal of sustainable development.

Job Requirements

Position |

Number |

|---|---|

|

MI Engineer |

2 |

|

QA Manager |

1 |

|

Drill Hole Supervisor |

1 |

|

Quality Assurance Director |

1 |

|

Mechanical and Electrical Engineer |

3 |

Join PEAK

Who is PEAK?

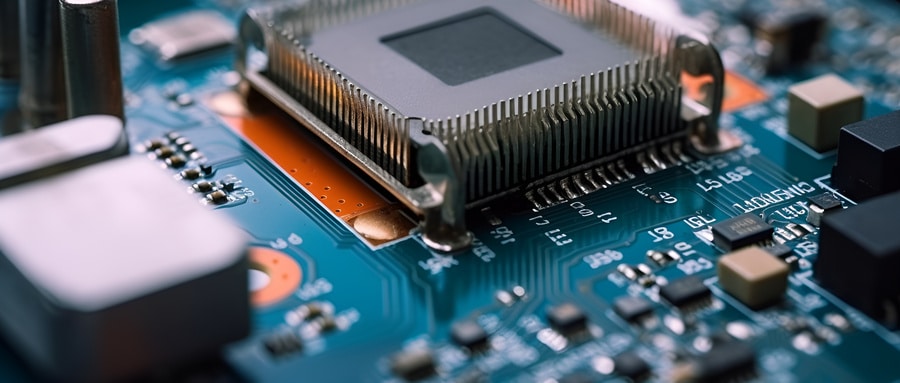

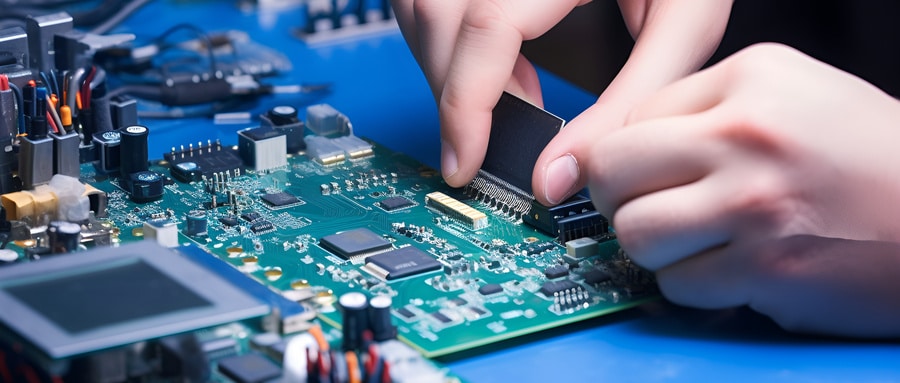

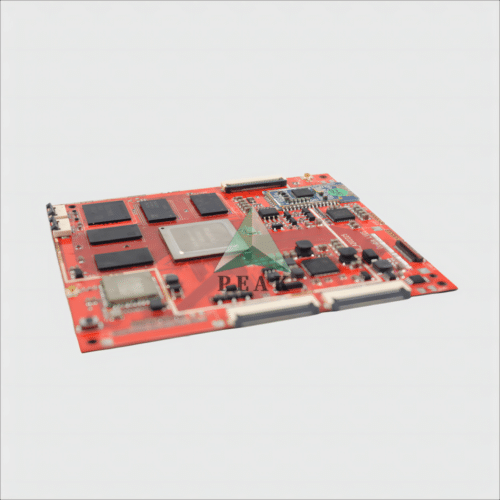

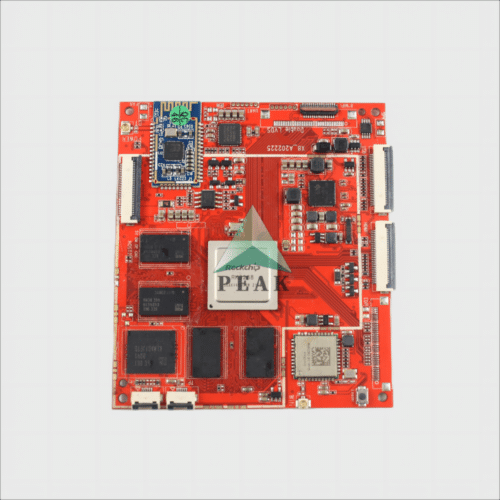

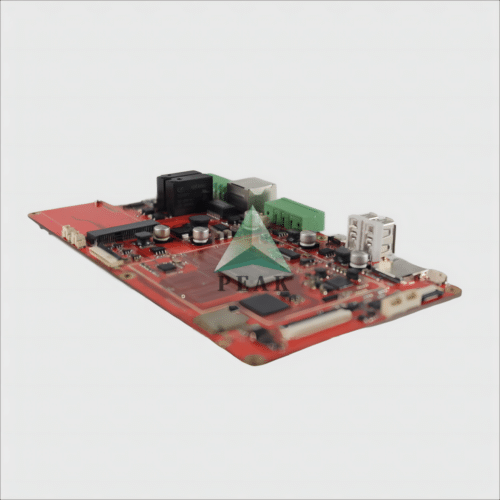

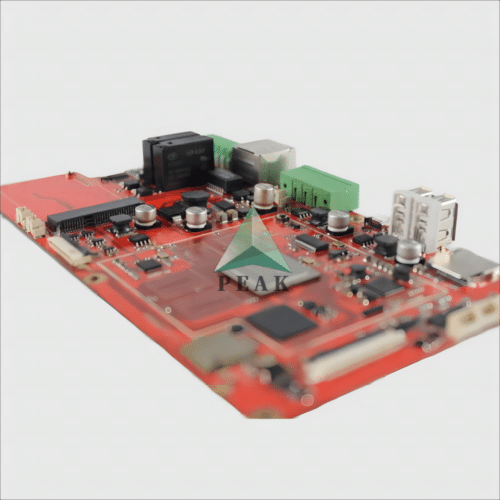

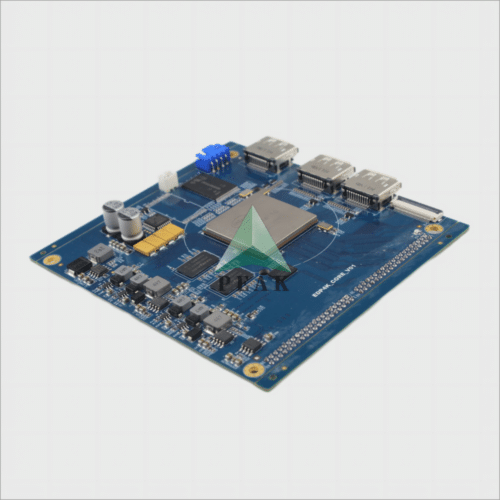

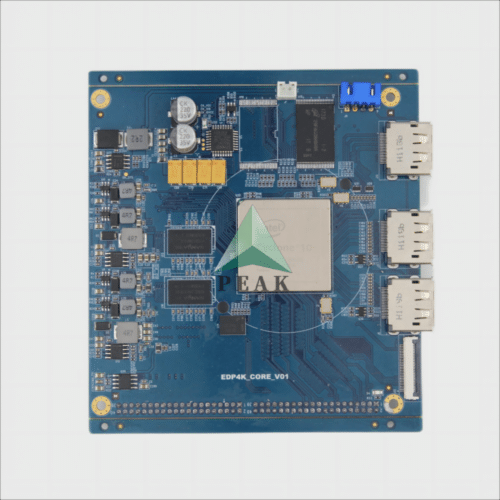

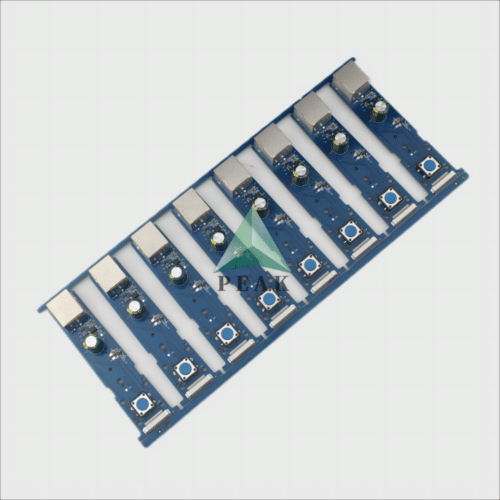

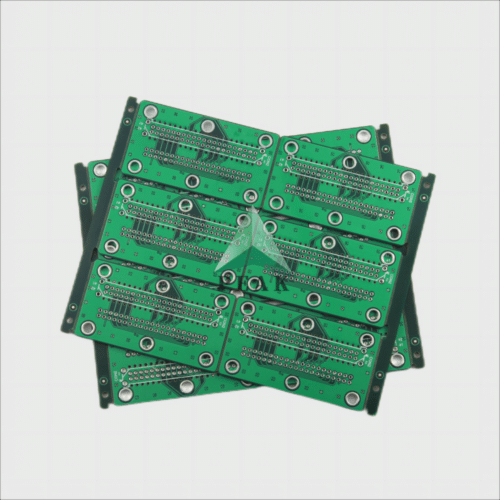

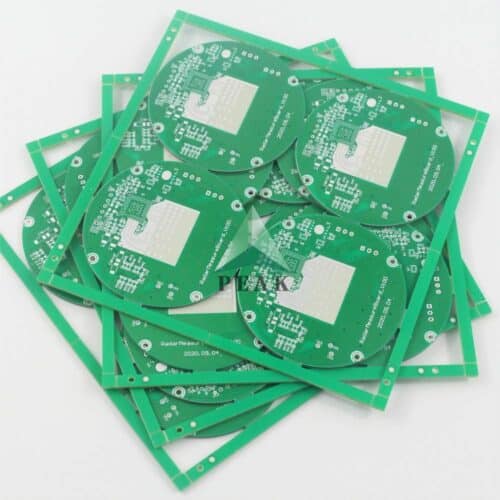

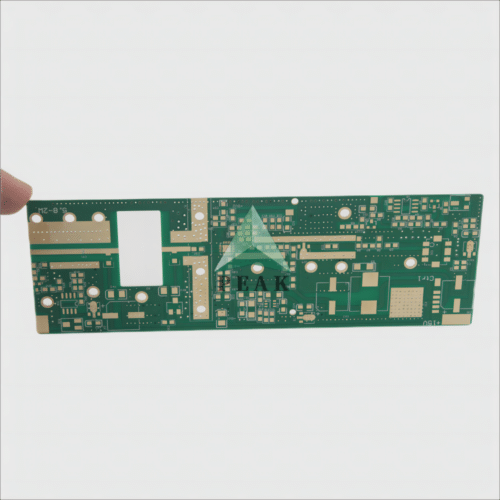

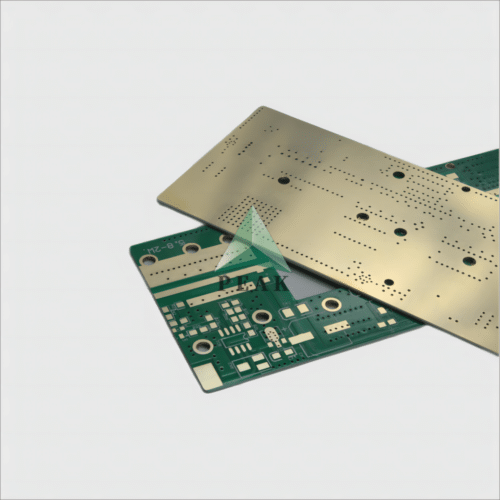

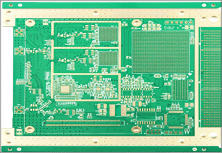

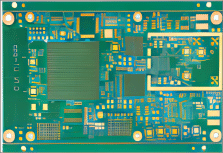

Founded in 2007, PEAK Co.,Ltd is an electronic solutions company offering 1-64 layers PCB fabrication, assembly, testing & validation of rigid, rigid-flex, HDI, high frequency, high speed, metal core, IC substrate, substrate-like and other special PCB. Our modern 54,000 square foot manufacturing facility allows us to provide all rigid & rigid-flex services under one roof and offer quick-turn capabilities. PEAK has a professional reputation for developing high-performance solutions for technically advanced OEM’s in a variety of markets including aerospace and defense, medical, computer, communication, server, semiconductor IC, automotives, industrial control, optoelectronics, LED and others.

Ability to Handle Complex Jobs

All Rigid & Rigid-Flex Services Under One Roof

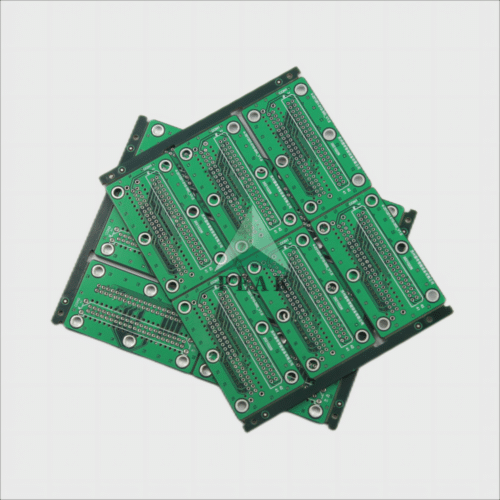

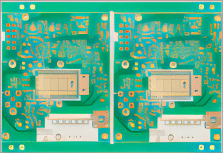

Regular PCB

Up to 64 Layers; FR4 TG135/TG150/TG170; Halogen Free/CTI≥600; Aspect Ratio (Finish Hole) 28:1; Sample Expedited 8 Hours(1-2Layer);

Metal Core PCB

Thermal Conductivity 1-398W/m.K; Aluminum/Copper AC 500-4000V; Post-bonding/Pre-bonding; Sweat-Soldering/Conductive Adhesive; Press-Fit/Embedded Coin(I, T U);

HDI PCB

Blind/Buried/Hybrid Via; 5+N(N+M)+5 Structure; Trace Width/Spacing 1.6/1.6mil; Laser Hole Size(mm)≥0.075; High Density Interconnector;

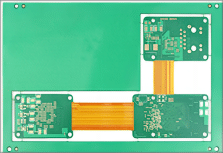

Rigid-Flex PCB

2-24 Layers; Book/Air-gap/Fly-tail; Unsymmetrical/Semi-Flex; Width of Flexible Zone 3mm(min); Dimension Accuracy ±0.05mm(min);

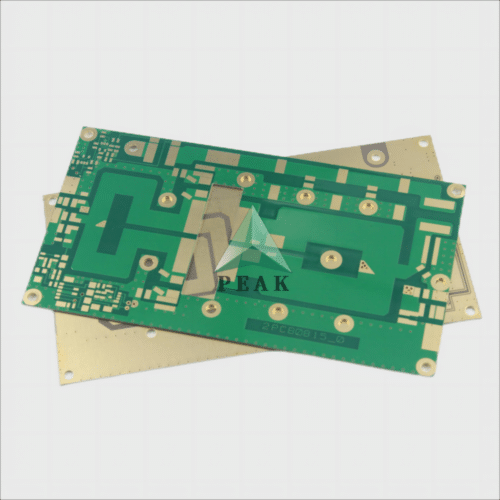

High Frequency PCB

More than 85+ Types; Rogers/Arlon/Taconic/Isola/ Nelco/F4B Serices,etc; Materials can be Specified; Impedance Tolerance ±5%(min);

Substrate PCB

CSP/FC-CSP/SIP/FC-BGA/WB-CSP; FR4/BT/High-Speed Material; Trace Width/Space 12/12μm; SM Registration:±20μm; Strict SM Flatness Control ≤5μm;

High Speed PCB

Panasonic Megtron4/6/7; TU-872SLK/Isola-FR408HR,etc; Impedance Tolerance ±5%(min); Dimension Accuracy ±0.02mm(min); Line Width/Space Accuracy ±5%;

Specialty PCB

Ceramic/Glass Material; Hybrid Material Lamination; Buried Capacitance/Resistance; PTH/NPTH Step Slots; Uneven/Segmented/Step Gold Finger;

The Complete Guide to Etching PCB – A Step-by-Step Process for DIY Enthusiasts

The Complete Guide to Etching PCB – A Step-by-Step Process for DIY Enthusiasts PCB etching is an indispensable skill for creating custom printed circuit boards (PCBs) at home, giving DIY enthusiasts the power to design and fabricate PCBs without outsourcing fabrication services. In this guide, we’ll walk through each step of

The Ultimate Guide to Cleaning PCBs – Tips and Techniques for Effective Maintenance

The Ultimate Guide to Cleaning PCBs – Tips and Techniques for Effective Maintenance Printed circuit boards (PCBs) form the backbone of modern electronic devices. As they contain complex circuits, components, and solder connections that require regular cleaning and maintenance for optimal performance and reliability, PCBs need regular attention as part

Understanding Vias PCB Design: Importance, Types, and Implementation

Understanding Vias PCB Design: Importance, Types, and Implementation Vias are essential components of printed circuit board design, acting as conduits that connect electrical connections between layers of the printed circuit board. Vias serve an important function by maintaining signal integrity, power distribution and thermal management – something we will explore

Understanding PCB Stackup: Importance, Considerations, and Best Practices

Understanding PCB Stackup: Importance, Considerations, and Best Practices PCB stackup refers to the arrangement of layers on a printed circuit board (PCB), including conductors, dielectric layers and any necessary components. It plays an integral part in determining its electrical and mechanical performance; we will explore its importance here as well

Exploring the Global (Printed Circuit Board) PCB Market: Trends, Growth, and Opportunities The printed circuit board (PCB) market plays an integral part of global electronics manufacturing. PCBs are intricately crafted boards used to connect and support electronic components. In this article, we’ll take an in-depth look at this global PCB

A Guide to PCB Repair: Tips and Techniques for Fixing Printed Circuit Boards

A Guide to PCB Repair: Tips and Techniques for Fixing Printed Circuit Boards Printed circuit boards (PCBs) are key components of electronic devices, providing connections for components to communicate and function efficiently. Unfortunately, PCBs may sometimes encounter issues that necessitate repairs; we will provide an extensive guide to PCB repair

Exploring OrCAD PCB Design Software for Efficient Circuit Board Development

Exploring OrCAD PCB Design Software for Efficient Circuit Board Development OrCAD PCB is an innovative design software used extensively in the electronics industry for efficient circuit board development. Thanks to its advanced features and user-friendly interface, OrCAD PCB enables designers to efficiently design complex layouts while validating designs and optimizing

DigiKey PCB Services – Streamlining Your PCB Prototype and Assembly Process

DigiKey PCB Services – Streamlining Your PCB Prototype and Assembly Process Digi-Key Electronics is a globally trusted distributor of electronic components and provides an array of products and services tailored to the needs of engineers, designers, hobbyists, hobbyists and more. One such offering by Digi-Key is PCB services which provide

Mastering the Art of Soldering PCBs – Tips for Successful Assembly Soldering is an integral step in the assembly of printed circuit boards (PCBs), as it creates electrical connections essential for electronic component functioning. Mastering soldering is key for creating reliable connections; in this article we’ll cover techniques and best

Assembly Services

PCBA Manufacturer PCB Board Assembly Programmable SMT PCB Assembly

Assembly Services

Customzied FR4 PCB HDI Assembly Manufacturing PCBA Multilayer PCB

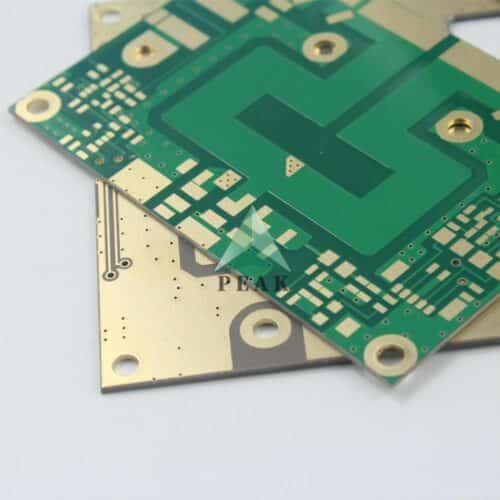

High Frequency PCB

ITEQ IT150DA (DK3.56; DF0.0047) Double Side Immersion Gold 1u PCB

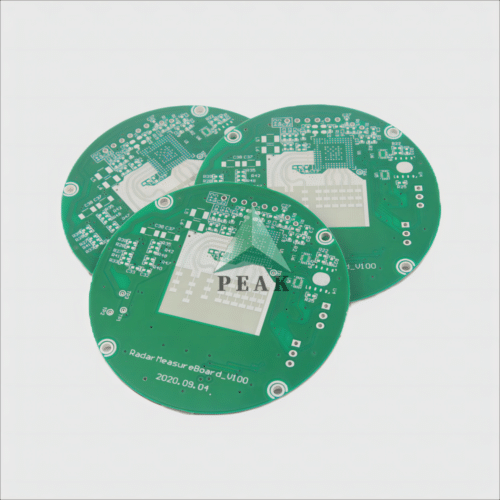

High Frequency PCB

4 Layers Blind Via SYTech SCGA-500 GF220 (DK2.20; DF0.0009) Radar PCB

PCB fabrication in as little as 8 hours

Our modern 54,000 square foot manufacturing facility allows us to provide all rigid & rigid-flex services under one roof and offer quick-turn capabilities.