Unlocking Thick PCB Boards: An In-Depth Guide

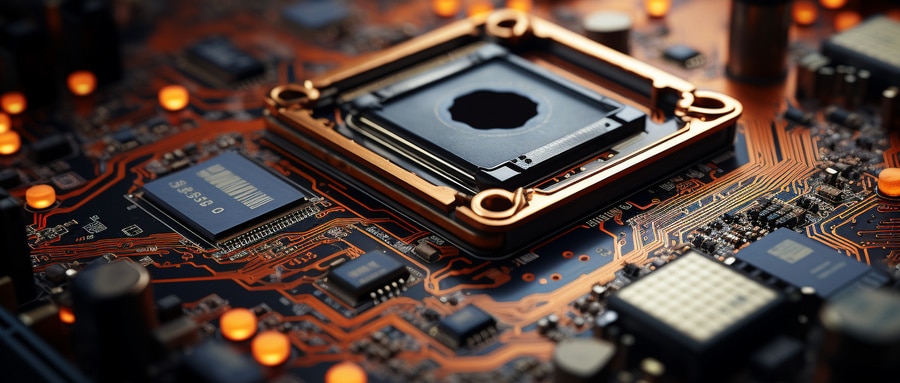

At the core of any electronics device lies an intricate network of connections known as Printed Circuit Board (PCB). PCBs have become indispensable parts of electronic assemblies and their significance cannot be overstated; among the wide variety of PCB types available today, one that stands out is thick PCB boards; in this article we’ll take an exploratory journey exploring their benefits, applications and the process involved in creating them.

PCBs come in various sizes and thicknesses, determined by the requirements and specifications of electronic devices into which they’re integrated. Thicker PCB boards stand out, with multiple reasons cited as justification for this trend.

Thick PCB boards tend to offer superior durability compared to thinner counterparts. Their extra thickness gives the board enhanced mechanical stability, making it less susceptible to damage during handling, installation or impacts from mechanical shocks or impacts – an attribute highly sought-after by industrial and automotive applications where robustness and reliability are of utmost importance.

Thicker PCB boards also boast increased heat dissipation capacities. As electronics become more complex, more heat is produced. Effective heat management relies on keeping devices cooler and improving performance – two benefits thick PCB boards offer.

Thick PCB boards also accommodate for higher component densities, making it possible for more complex circuit designs and electronic components to fit on these boards. This capacity makes thick PCB boards particularly useful in high-tech sectors like aerospace, defense and telecom where electronic devices are an everyday reality.

Manufacturing thick PCB boards is similar to producing standard boards with additional steps added in to enhance their thickness. Starting with designing the circuit layout and then etching it onto PCB material, followed by multiple rounds of Electroless Copper Plating until reaching desired thickness, followed by solder mask coating as an extra protective measure and finally assembly of electronic components onto the board.

Thick PCB boards have numerous practical uses in modern society, from automotive control systems and heavy industrial machinery, networking hardware, high-speed servers, aerospace navigational systems and medical imaging devices. Their robustness, thermal characteristics and ability to accommodate complex circuits make them the perfect choice in these sectors.

Thicker PCB boards play an indispensable role in electronics technology. Their durability, enhanced heat dissipation, and increased component density make them highly sought-after features. As with any technology decision, selecting an optimal PCB board should take into account your specific device requirements for maximum effectiveness – thus further expanding electronics tech frontiers.

This in-depth exploration serves as a guide, while providing more light on this crucial yet often neglected aspect of electronics technology. Learning the essentials behind thick PCB boards can assist both individuals and industries alike in optimizing electronic devices and assemblies to perform at their highest potential levels. Join us on this exciting journey of uncovering their full potential within electronics technology!

Thick PCB Board FAQ:

- What is a Thick PCB Board?

A thick PCB board, typically refers to PCBs that have a thickness greater than the standard thickness. The average thickness of a standard PCB is usually 1.6mm (0.063 inches). Any board with a thickness greater than this can be considered a “thick” PCB. - What are the Advantages of Thick PCB Boards?

Thick PCB boards often offer increased durability and can better withstand physical stress and harsh environments. They can also better manage high-current applications, and can provide ample space for larger components and complex circuitry. - How is the Thickness of a PCB Board determined?

The thickness of a PCB board is influenced by several factors, including the type and number of layers, the thickness of the substrate, the thickness of the copper layers used, and the specific requirements of the end application. - Can any PCB be manufactured in a Thick version?

Technically yes, however, it’s important to remember that using a thick PCB may not be suitable for all types of applications. For example, portable or compact electronic devices typically require more slim and lightweight PCBs. - Does a Thick PCB Impact Assembly Process?

Yes, a thick PCB can impact the assembly process. Due to the increased thickness, additional considerations may need to be made for component placement and connection methods. Also, thicker PCBs might necessitate longer or more intense heating during the soldering process. - How does the Thickness of a PCB Board affect its Performance?

The thickness of a PCB board can affect its heat dissipation, electrical performance, and mechanical stability. Thicker boards can often handle higher currents and have better heat dissipation properties, but they are also heavier and might not be suitable for all types of devices. - What are Typical Applications of Thick PCB Boards?

Thick PCB boards are typically found in applications that require strong physical support, high power handling, or high levels of thermal management. Some examples include industrial machinery, automotive systems, power supplies, and server hardware. - What is the Maximum Thickness of a PCB Board that can be Manufactured?

Depending on the specific manufacturer’s capabilities, PCBs can be made with a thickness up to 3.2mm (0.126 inches) or more. However, it’s important to consult with your PCB manufacturer for exact capabilities and limitations. - Does a Thick PCB Board Cost More?

Because thicker PCBs require more material and may require additional time or specialized processes during manufacturing, they typically cost more than thin or standard thickness PCBs. - How do I Specify the Thickness I need when Ordering a PCB Board?

The desired thickness of a PCB is typically specified during the design phase and will be included in the documentation provided to the manufacturer. Communication with your manufacturer during this phase is vital to ensure your design requirements can be met.