Demystifying ENIG PCBs: A Deep Dive into Electroless Nickel Immersion Gold Technology

The world of printed circuit boards (PCBs) continues to progress as efficiency and compactness become key requirements of modern electronics. One such advancement are ENIG PCBs. Utilizing an Electroless Nickel Immersion Gold (ENIG) coating, these PCBs have unrivalled benefits – this comprehensive guide broadens your understanding on this subject matter.

This article will focus on three sections of focus. These sections include:

- Introduction to ENIG PCBs

- Understanding the ENIG Process

- Understanding Key Benefits of ENIG PCBs

- Limitations of ENIG PCBs

- Applications for ENIG PCBs

- Comparing with Other PCB Finishes

- Future Perspective of ENIG PCB Technology

Introduction to ENIG PCBs

Start out right by understanding what ENIG Printed Circuit Boards are and the Electroless Nickel Immersion Gold technique; an innovative process which ensures flat surfaces with excellent solderability and extended shelf lives.

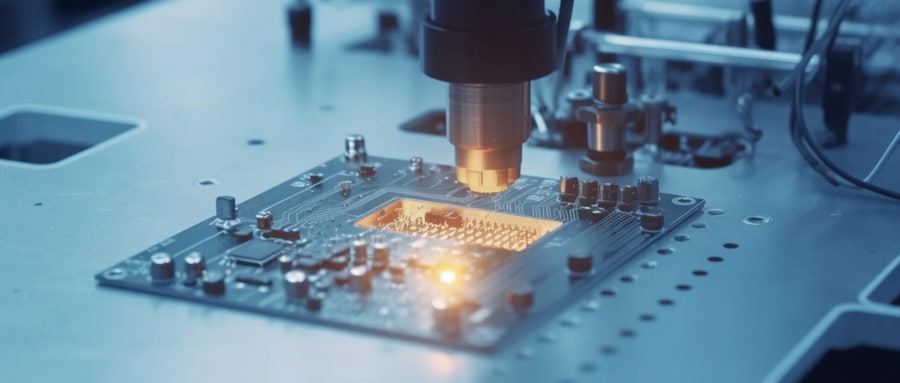

Understanding the ENIG Process

Take a step-by-step journey with ENIG Printed Circuit Boards from cleaning and micro-etching of copper surfaces through to concurrent deposition of nickel and gold layers, which showcases their technical expertise.

Understanding Key Benefits of ENIG PCBs

ENIG PCBs boast many advantages over standard printed circuit boards (PCBs) including excellent surface planarity, optimal electrical performance and strong corrosion resistance. In this section we delve deeper into these benefits, giving a clear picture as to why ENIG Printed Circuit Boards have become so widely adopted in electronics manufacturing industries worldwide.

Limitations of ENIG PCBs

Gain insight into the limitations associated with ENIG Printed Circuit Boards, such as cost considerations and risk of black pad syndrome. This section presents both their utilities and potential drawbacks in order to form an accurate view of this technology.

Applications of ENIG PCBs

Discover the numerous uses for ENIG PCBs. From telecom to medical device use cases, find out why and when ENIG PCBs are preferred over their competitors.

Comparison of ENIG with Other PCB Finishes

How does ENIG compare with other PCB surface finishes, like HASL, OSP or ENEPIG? This section equips you with all of the information required to make informed choices for your PCB projects.

Future of ENIG PCB Technology

Ungain insight into the future of ENIG PCBs, potential advancements in technology and its ramifications on PCB design and electronics more generally.

This guide offers an all-encompassing view of ENIG Printed Circuit Board technology. From basics to expert insight, this information can assist with specific PCB needs – making you a more adept PCB designer or electronic enthusiast in general. Embark upon an exploration of ENIG Printed Circuit Boards as they may lead the success of your next project!

FAQ:

- Q: What is an ENIG Printed Circuit Board?

A: An ENIG (Electroless Nickel Immersion Gold) Printed Circuit Board is a type of PCB which uses a gold surface finishing method for the solder pads. This provides long shelf-life, good corrosion resistance, and excellent surface planarity. - Q: What are the benefits of using ENIG Printed Circuit Board?

A: ENIG finish results in a highly reliable solder joint, offers excellent surface planarity, and is superb for fine pitch/bump components (BGA, Flip Chip), and flat surfaces. - Q: What are the downsides of ENIG Printed Circuit Board?

A: The two primary downsides are cost and the risk of what’s called “black pad syndrome” (nickel corrosion) which could negatively affect solder joint integrity. - Q: Why would I choose an ENIG finish over other finishes?

A: ENIG offers a flat surface, long shelf-life, and good corrosion resistance, which makes it an excellent choice for fine-pitch components where coplanarity is crucial. - Q: How does ENIG Printed Circuit Board prevent oxidation?

A: The nickel under the gold layer of an ENIG Printed Circuit Board helps prevent the copper from oxidizing. - Q: Is ENIG Printed Circuit Board more expensive than other PCBs?

A: Yes, ENIG Printed Circuit Boards are generally more expensive than other PCBs with different finishes due to the use of gold. - Q: How is an ENIG Printed Circuit Board produced?

A: ENIG Printed Circuit Board is produced by first cleaning the bare copper, then applying a layer of nickel via electroless nickel-plating, followed by a thin layer of immersion gold. - Q: Are ENIG Printed Circuit Boards RoHS Compliant?

A: Yes, ENIG finish is RoHS compliant. It is lead-free and does not use any restricted substances. - Q: How reliable is an ENIG finish?

A: ENIG provides a highly reliable solder joint and excellent shelf life, making it highly reliable. However, there’s a risk of “black pad syndrome.” - Q: What applications benefit the most from ENIG Printed Circuit Boards?

A: Applications requiring superior planarity, such as BGA and chip-scale packages, or long assembly shelf-life can greatly benefit from ENIG Printed Circuit Boards.