Frequently Asked Questions: What are PCB Boards Made of?

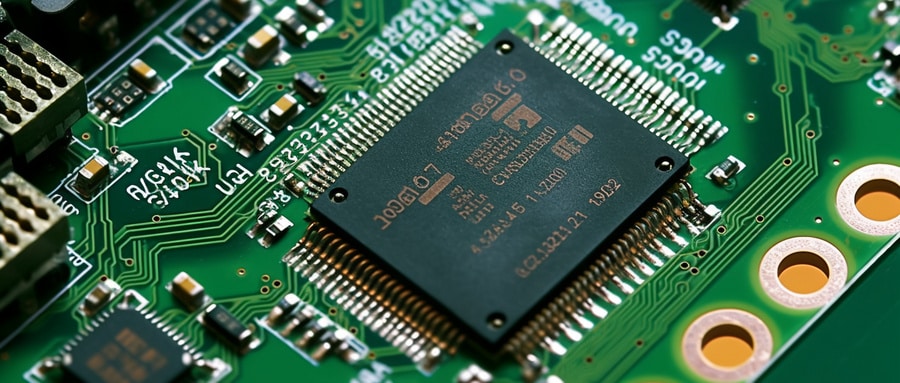

PCBs, or Printed Circuit Boards, are a labyrinthine network of tiny electrical paths etched on a physical surface. This is made possible through the fusion of various materials. PCBs, the unsung heroes of our technology, are at the heart of all gadgets and electronic devices. They transform abstract codes into functionalities. Understanding their composition is crucial to appreciating the underappreciated glory of PCBs.

Let’s look at the materials that are the foundation of these technological wonders.

What are PCB Boards Made of?Substrate Materials:

The substrate, or base material of PCBs, is usually made of fiberglass. More specifically, FR4-grade fiberglass. The FR stands for fire retardant, a safety feature that is required for electrical components. The structural strength of fiberglass is enhanced by its robustness, and its electrical insulation properties help to prevent unwanted conductivity.

What are PCB Boards Made of?Copper :

All conductive elements of a PCB, from the micro-lanes that cross the surface to the wide highways which transfer power are made out of copper. Copper’s high conductivity, corrosion resistance, and malleability makes it an ideal material for complex circuitry.

What are PCB Boards Made of?Solder Mask:

This characteristically-green layer, also known as a solder shield, surrounds the circuit board and acts as a shoulder to the copper. It is made from a polymer coating that insulates the copper tracks and prevents accidental crossing of paths.

What are PCB Boards Made of?Silkscreen :

The silkscreen layer adds a final touch of personality to the PCB board. The silkscreen layer is the topmost PCB layer that labels critical components using alphanumerical or symbolic representations. Silkscreen is usually made of epoxy ink.

These components all play a part in creating the PCB’s grand symphony. They work together to produce a durable, functional printed board.

These components were not selected randomly, but rather as a result of a meticulous research. The goal is to find a balance among cost-effectiveness and performance while also meeting safety regulations. The advancement of technology also introduces new materials to this world like metal-core or polyimide PCBs, which are used for specific applications. This keeps the future of the PCBs exciting.

PCBs are a good example of diverse materials combining into a well-organized assembly that gives birth to productivity and functionality. Understanding what these everyday components are is important as we move into an age of automation and digitization.

This article is intended to provide a thorough understanding of PCB materials. Next time you look inside your computer, or turn on the light, stop to admire the PCB board. It is a testament to human ingenuity and creativity. Our journey continues into the mysterious world of PCB, where there are still many more layers to discover and understand.

The Printed Circuit Board market (PCB) is poised for a number of exciting developments in the future. This will be largely due to the technological advances and the increasing demand across various sectors.

- High-Density Interconnect Technology (HDI): The trend towards miniaturization in electronics has encouraged the development of PCBs that are more compact and efficient. HDI technology allows more components to fit on both sides of a PCB. This increases functionality without increasing the size.

- Green PCBs: In the future, sustainability will be more important. Green PCBs will play a greater role in the future, as they are produced with a reduced impact on the environment.

- Flexible and rigid-flex printed circuit boards will grow significantly with the growing demand for flexible electronic products in industries such as automotive, consumer electronics, and medical.

- IoT and smart devices: PCBs will be in greater demand as the internet of things (IoT), and smart devices, grow. These devices are made up of PCBs, and IoT growth will increase the demand for these boards.

- Automobile Industry: As electric and self-driving cars become more common, PCBs will have new opportunities as they require complex electronic systems.

- AI and ML: Artificial Intelligence (AI) and Machine Learning applications will also require advanced, high-speed circuit boards for efficient operation.

- 5G Communications: As 5G technology takes off, PCB technology will need to be improved. This includes materials and designs capable of handling high-frequency signals.

- The future may see new materials developed that can replace the traditional ones while balancing affordability with performance and durability.

The trajectory of PCB growth will depend, of course on many factors, such as technological advances, regulatory environments, and market demands. The PCB industry is expected to continue growing and progressing.