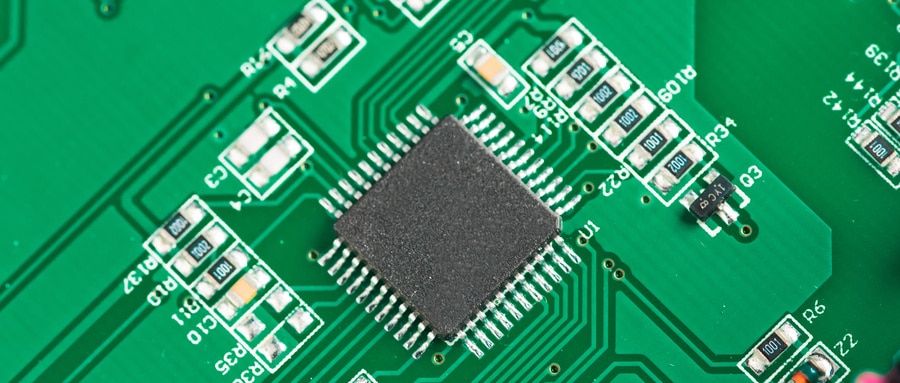

Resin plug hole hdi pcb, an important technology for modern electronics

– Using a resin plug to fill in holes on a high-density interconnect (HDI) PCB

High-density interconnect (HDI) printed circuit boards (PCBs) are becoming increasingly popular due to their ability to pack more components into a smaller space, leading to smaller and more powerful electronic devices. However, HDI PCBs also come with their own set of challenges, one of which is dealing with the small holes created during the manufacturing process.

These holes, known as microvias, are drilled into the PCB to allow for the connection of internal copper layers. However, in some cases, they may be accidentally drilled in the wrong place or be too small for the intended copper trace. This can result in short circuits or open connections, both of which can render the PCB useless.

One solution to this problem is to use a resin plug to fill in the hole. A resin plug is a small amount of epoxy that is injected into the hole, filling it completely and creating a solid surface for subsequent layers to be built on. This process is known as via filling.

There are several advantages to using a resin plug for via filling. Firstly, it provides a solid surface for subsequent layers to be built on, ensuring that there are no open connections or short circuits. Secondly, it allows for the use of smaller vias, which can increase the density of the PCB and ultimately lead to smaller and more powerful devices. Finally, it can also help to reduce signal loss and improve overall signal integrity.

The process of via filling with a resin plug is relatively straightforward. After the hole has been drilled, the resin is injected into the hole using a syringe. The resin is then cured using heat or UV light, depending on the type of resin used. Once the resin has cured, the surface can be sanded or polished to ensure that it is level with the surrounding surface.

However, there are some potential drawbacks to using a resin plug. Firstly, it can be time-consuming and may add an additional step to the manufacturing process. Secondly, the resin plug may shrink slightly during the curing process, which can lead to stress on the surrounding copper trace. Finally, if the resin is not properly cured, it can leach out and cause contamination of other components on the PCB.

In conclusion, using a resin plug to fill in holes on a high-density interconnect PCB can be an effective way to ensure that the PCB is free of open connections and short circuits. While there are some potential drawbacks to consider, the benefits of increased density and improved signal integrity make it a popular choice for many manufacturers.

-What is Resin Plug Hole HDI PCB?

The resin plug hole HDI PCB is a printed circuit board that uses high-density interconnect technology and has resin-filled through-holes. The resin plug hole technology is used to fill the holes of the PCB with resin, which enhances the board’s reliability and durability. The resin fills the holes and forms a solid and reliable connection between the layers of the board. This technology is particularly useful in high-vibration environments where the components may otherwise become loose or damaged. The resin plug hole HDI PCB is commonly used in complex electronic devices such as smartphones, tablets, and other portable electronics.

In addition to its reliability, the resin plug hole HDI PCB also offers several other benefits. First, it allows for higher circuit density, meaning that more components can be placed on the board without increasing its size. This is particularly important for portable devices, where space is at a premium. Additionally, the resin plug hole technology can improve signal integrity by reducing electromagnetic interference between the layers of the board. Finally, the use of high-density interconnect technology means that the board can support more complex circuits, allowing for advanced features and functionality.

Overall, the resin plug hole HDI PCB is an important technology for modern electronics. Its combination of reliability, density, and functionality make it a popular choice for manufacturers of high-end consumer electronics. As technology continues to advance, it is likely that we will see even more complex and advanced PCBs using resin plug hole technology.