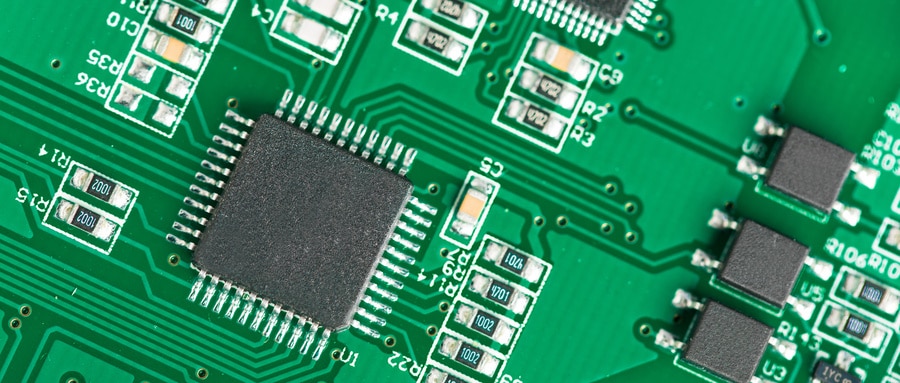

Aerospace PCB assembly,advanced and reliable manufacturing process

– Use of advanced manufacturing processes to ensure high-quality and reliable PCB assembly for aerospace applications

The aerospace industry demands high-quality and reliable printed circuit board (PCB) assembly for its various applications. PCBs are the backbone of electronic devices, and their assembly requires precision, accuracy, and attention to detail. As the industry continues to evolve, advanced manufacturing processes are becoming increasingly popular to ensure that the PCBs meet the industry’s stringent standards.

One of the significant benefits of advanced manufacturing processes is the integration of automation, which reduces human error and increases consistency. Automation has proved to be a game-changer, especially in the aerospace industry, where quality and reliability are paramount. Automation can perform tasks such as soldering, dispensing, and inspection, which are critical in the production of high-quality PCBs.

Another advantage of advanced manufacturing processes is the use of cutting-edge technologies and equipment. These technologies are designed to improve precision and accuracy, making it possible to produce intricate PCBs with complex designs. For instance, advanced pick-and-place machines can place components with a high degree of accuracy, reducing the chances of errors. Additionally, new inspection technologies such as automated optical inspection (AOI) machines can detect defects that might have been missed by manual inspection.

Furthermore, advanced manufacturing processes promote standardization. Standardization ensures that all the PCBs produced are of the same quality, regardless of the production batch. It also reduces the time and cost of production, making it easier to scale up production when necessary. Standardization also makes it easier to troubleshoot issues and identify the root cause of defects, making it possible to resolve issues promptly.

While advanced manufacturing processes have several benefits, they also come with their own set of challenges. The cost of acquiring and maintaining the necessary equipment can be high, making it difficult for small and medium-sized businesses to adopt them. Additionally, the initial setup and calibration of the equipment can be time-consuming, requiring specialized knowledge and expertise.

Advanced manufacturing processes are essential in ensuring high-quality and reliable PCB assembly for aerospace applications. They offer several benefits, including automation, precision, standardization, and the use of cutting-edge technologies. However, they also come with their own set of challenges, including high costs and specialized knowledge requirements. Despite these challenges, the aerospace industry must embrace advanced manufacturing processes to stay ahead of the competition and provide quality products to its customers.

– Integration of advanced technologies such as IoT, AI, and machine learning to optimize efficiency and performance of aerospace PCB assembly processes.

The integration of advanced technologies such as IoT, AI, and machine learning has revolutionized the aerospace PCB assembly processes. IoT devices enable real-time monitoring of the assembly line, providing insights into the performance of machines and the status of components. AI algorithms can analyze the data collected by IoT devices, predict potential issues, and provide recommendations for optimization. Machine learning algorithms can also be used to identify patterns and optimize processes by learning from historical data. Overall, the integration of these technologies has enabled aerospace manufacturers to achieve higher levels of efficiency and performance, reducing costs and improving product quality.

FAQ:

1. What is aerospace PCB assembly?

2. What are the specific requirements for aerospace PCB assembly?

3. What are the challenges in aerospace PCB assembly?

4. What is the difference between aerospace PCB assembly and regular PCB assembly?

5. What materials are commonly used in aerospace PCB assembly?

6. What are the testing procedures for aerospace PCB assembly?

7. How do you ensure the quality of aerospace PCB assembly?

8. What certifications are required for aerospace PCB assembly?

9. What is the lead time for aerospace PCB assembly?

10. What are the cost considerations for aerospace PCB assembly?